Which Blow Molding Process is Ideal for your Bottle?

Blow molding is a manufacturing process for forming and joining hollow plastic parts together. In general, there are three main types of blow molding: Extrusion Blow Molding, One Stage Injection Blow Molding, and Two Stage PET Stretch Blow Molding.[1]

Basically, blow molding is intended for use in manufacturing hollow plastic products, such as bottles and other containers. However, the process is also used for the production of toys, automobile parts, accessories, and many engineering components. The principles used in blow molding are essentially similar to those used in the production of glass bottles. Although there are considerable differences in the process available for blow molding, the basic steps are the same: (1) melt the plastic; (2) form the molten plastic into a parison (a tubelike shape of molten plastic); (3) seal the ends of the parison except for one area through which the blowing air can enter; (4) inflate the parison to assume the shape of the mold in which it is placed; (5) cool the blow molded part; (6) eject the blow-molded part; (7) trim flash if necessary. Two basic processes of blow molding are extrusion blow molding and injection blow molding. These processes differ in the way in which the parison is made. The extrusion process utilizes an unsupported parison, whereas the injection process utilizes a parison supported on a metal core. The extrusion blow-molding process by far accounts for the largest percentage of blow molded objects produced today. The injection process is, however, gaining acceptance. Although any thermo-plastic can be blow-molded, polyethylene products made by this technique are predominant. Polyethylene squeeze bottles form a large percentage of all blow molded products. Air pressure is utilized to inflate soft plastic into a mold cavity during the molding process. Used in the manufacture of one-piece hollow plastic items with thin walls, such as bottles. Because these commodities are used in mass markets for consumer beverages, production is usually organized by quantity.

In two steps, it was completed:

- Constructing a starting tube.

- Inflate the tube to the final shape required.

The parison can be formed using either extrusion or injection molding.

EXTRUSION BLOW MOLDING

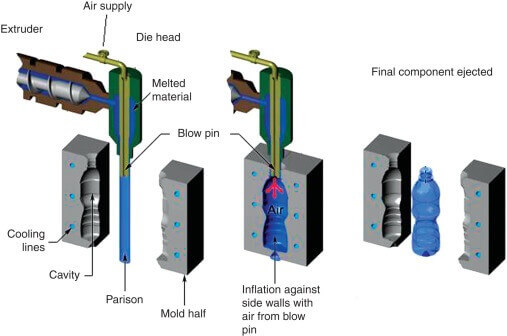

In terms of blow moulding, extrusion is the most basic. Using an extruder and a water-cooled mould, a parison, or hot plastic tube, is caught in a piece of plastic. Just like when you're blowing a balloon, air is pumped into a mould once the moulds have been closed. Material is fed into a feeding transfer screw in extrusion blow moulding via a feeding hopper. In order to make the parts, an extrusion blow moulding machine uses a hollow tube as a tool. We call this tube a parison. To blast the parison, the hollow mould closes around it. As another parison is being extruded from the machine, air pressure is used to mould the parison inside of the mould. As a result, the production process can be completed more quickly (Figure 2).

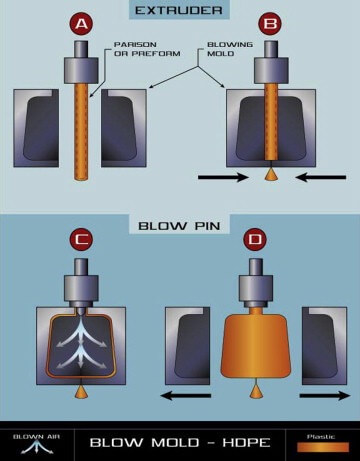

Figure 1 Extrusion Blow Mold[2]

Figure 1 Extrusion Blow Mold[2]For making parisons, the material is extruded into a hollow tube using a specially constructed blow moulding die. Compared to injection blow moulding, extrusion can manufacture larger pieces. It is also less expensive because there are no internal tensions in the part. Extrusion blow moulding, on the other hand, generates more waste and offers less control over the precision of essential dimensions. It is possible to run extrusion blow moulding as a continuous or semi-continuous process, depending on the specific application.

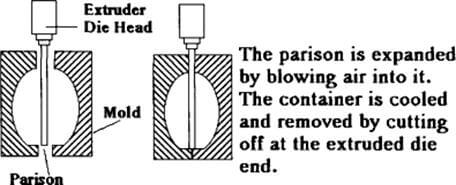

Material is fed into a feeding transfer screw in extrusion blow moulding via a feeding hopper. A specific blow moulding die is used to direct the flow of material into a hollow tube known as a parison. Gravity causes this parison to fall until it reaches a predetermined length, at which point the mould closes around it and seals the bottom edge (that gives the distinctive end seal). The parison is cut open, and a blow pin moves to the top of the tool and inflates the parison against the tool cavity's walls with the use of a cutting knife. Once the mould has solidified, it is ejected from the mould and the process restarts with the new parison that was extruded. Figure 2 depicts a diagrammatic representation of the system. [2]

Figure 2 Extrusion Blow Moulding[2]

Figure 2 Extrusion Blow Moulding[2] Figure 3 Extrusion blow molding[2]

Figure 3 Extrusion blow molding[2]Most petrochemical and lubricant containers are made by blow molding method, and HDPE or LDPE is commonly used as material. The examples are plastic fuel tanks、motor oil bottles、petrochemical tanks、jerry cans、lubricants、glue grease, etc. Sometimes multiple layers technique is applied to those containers because it can improve the gas barrier properties and further longer the storage life. Also, it can be more eco-friendly and cost-saving due to recycled materials using. Chia Ming is experienced in multi-layer technique and is able to advise you how to archive your goal. Please see our CM-L Series Co-Extrusion Blow Molding Machine as reference or contact us for more information.

Food packaging is used to fill from thin liquids to thick liquids. The examples of thin liquids are soy sauce, vinegar, cocktail sauce, edible oil, juice, etc. Milk bottle, yogurt, lactic acid drink, butter, jam, paste, tomato sauce, honey, mustard, salad dressing, mayonnaise, ketchup, vinaigrette, chili sauce, and so on are examples of thick liquids. Mayonnaise, ketchup or sauces which are oxygen sensitive usually require multilayer packaging in order to preserve the products. Some products also need an acid resistance layer or UV barrier to keep food safe and extend shelf-life. CM-L Series Co-Extrusion Blow Molding Machine is the model adaptable for those applications.

Also, CM-40 Series Pneumatic Extrusion Blow Molding Machine and CM-R Series Pneumatic Extrusion Blow Molding Machine are highly appropriate for production of popsicle or frozen bar in various forms.

The examples are liquid detergent, floor cleaner, floor polish, glass cleaner, kitchen spray, dish soap, bleach, bath cleaner, bathroom spray, car polish, degreaser, etc.

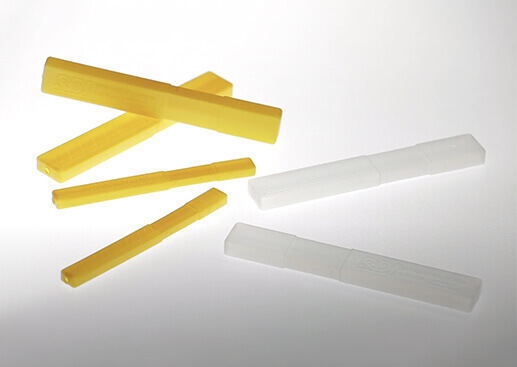

Bellows plunger is a special product made by our CM-S/D/T/F H 2D Series Continuous Extrusion Blow Molding Machine which is also equipped with deflashing device and parison control to achieve the perfect shape and thickness.

Pharmaceutical or biomedical products use various plastic for packaging. HDPE jars are usually applicable to medical pills, capsule, vitamin supplements, daily supplements, health protection medicine, powder shake, nutrition supplements, protein shake, collagen powder, etc. LDPE is frequently used for liquid products such as syrup, cough medicine, Lodine, liquid vitamin, liquid stomach relief, nasal rinse, nasal spray, eye drop, contact solution, oral liquid, enema, etc. This is the example of protein shake jar.

PVC is used for oxygen masks, and PP is usually used as drip bottle.

CM-40 Series Pneumatic Extrusion Blow Molding Machine is appropriate for small containers like drug bottles and cough syrup.

Personal care products use PET, PP, PE as packaging widely. The examples are shampoo, hair conditioner, hair colourant, body lotion, face cream, face lotion, skin moisturizer, skin toner, skin cream, perfume, sun cream, sun lotion, sun oil, sunscreen, mascara, essential oil, makeup remover, face cleanser, hair styling gel, hand cream, massage oil, facial mask, mud mask, liquid bubble bath, intimate oil, nail polish remover, shower gel, etc.

Blow molding machine is capable of making different kinds of forms such as toys, bellows, blade case, roll on balls, tool box, tea pot, car parts, table, road block, dumbbell, plastic sports equipment、tree decorations, etc.

INJECTION BLOW MOLDING (ONE STAGE) PROCESS

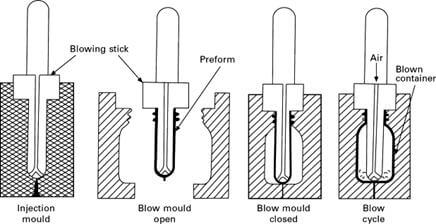

By injecting the plastic preform and then transferring it to the blow mould station by means of a rod, the preform is formed and then shaped by air pressure according to the design of the female blow mould in this process known as injection blow moulding. A typical injection moulding machine could execute a single stage injection blow moulding process without preform storage and reheat in order to produce small series of customized hollow parts. After a short cooling period, the preform is blown moulded. [3]

It's best to use polypropylene (random copolymer) for this type of application. Temperature gradients, molecular orientation, high stretch rates, and high cooling rates are all a part of this single-stage process. It's simple. Smaller processing windows result from the constraints. The preform must be sufficiently heated to be blown so that the process occurs between melting and crystallization temperatures. The single-stage injection blow moulding technology is now accessible on ordinary injection moulding machines.

Blow molding and injection moulding are handled by a single tool in an injection mould. As a result, its proportions match those of a typical injection moulding machine. Having the two steps in the same mould results in a more restrictive procedure than the typical one. Temperature gradients, molecule orientation, high stretch rates, and high cooling rates are all introduced throughout this procedure. This results in a narrow window of opportunity for processing. It is necessary to keep the preform molten enough to be blown in order for the process to occur between the melting point and crystallization point.

Figure 5 Injection Blow Molding[3]

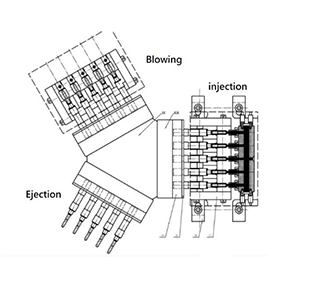

Figure 5 Injection Blow Molding[3]A Single-Step Infusion for mass production of small medicinal and single-serve bottles, IBM (Blow Molding Machine) is employed. Injection, blowing, and ejection are the three stages of the Injection Blow Molding process. In order to melt the polymer, an extruder barrel and a screw assembly must be used in conjunction. Hot runners are used to inject the polymer into the heated cavities and core pins of the mould. The external shape of the preform is created by the cavity mould, which is clamped around a core rod to create the inside shape. To create the body, a thick polymer tube is bonded to the neck of the bottle/jar. Using a core rod that has been clamped into a hollow, cooled blow mould after being turned in the preform mould, the preform is completed. [3]

A small hole in the core rod allows pressurized air to enter, inflating the preform into its final form. The blow mould is opened and the core rod is rotated to the ejection position after it has been allowed to cool for a period of time. As an alternative, the finished product can be leak-tested prior to shipping. It is common for preforms and blow moulds to have three to sixteen cavities, depending on the part size and production. It is possible to simultaneously inject, blow mould, and expel a preform using three core rods.

Figure 6 One Step Injection Blow Molding Machine (IBM)[3]

Figure 6 One Step Injection Blow Molding Machine (IBM)[3]- Soda、juice、water bottles.

- Shampoo and cleaning containers.

- Cosmetics bottles.

- Medical packaging.

- Drums made of plastic.

- Tubs.

- Furthermore, there's more.

Stretch Blow moulding machines capable of producing over 3000 bottles per hour produce beverage, food packaging containers and cleaning supplies.

The necks and other dimensions of most pill and cosmetic bottles must be precisely measured. Another ideal match for this business is the One Stage Injection Blow Molding Machine. Plastic blow moulded bottles ranging in size from 5 ml to 2 liters are available in a wide variety of designs.

Detergent and laundry bottles as well as liquid soap and lotion bottles are some of the most commonly moulded Injection Blow Molding Parts in hotels and our daily lives. [3]

INJECTION STRETCH BLOW MOLDING (TWO STAGES)

Injection Stretch Blow Molding (ISBM) uses the Injection Molding method to mould the plastic into a 'preform'. In the production of these preforms, the necks and threads of the bottles, known as the finish, are incorporated. To make these preforms, the Blow Molding method is used.

It is possible to make high-quality bottles with great clarity using stretch blow moulding, which is a type of blow molding.

The technique used in two-stage injection stretch blow molding machines involves two machines. These are the injection molding system and stretch blow molding machine.

Here, the plastic is molded into a fully-cooled preform in the first machine before being shipped to the second machine.

The preform will usually feature the neck of the bottle as well as its thread, and it can be sold to a third party even before it is blown using the second machine.

When received by the latter, they are then unscrambled, reheated using infrared radiation, and conditioned before molding.

The need to cool the preform before reheating and stretching also gives this process its name, the “cool preform method“.

During two-stage injection blow molding, the preform is completely cooled and then transferred to another machine to be blown into the final shape. The preforms must be reheated and then blown. By using two-stage, shipping costs can be lowered by shipping preforms as opposed to shipping empty bottles to a bottling plant. The bottles are then blown at the bottling plant prior to filling.

5 Gallon PET drum is the perfect example of saving shipping costs by shipping preforms than empty bottles. CMS-Q1 Series PET Fully Electric Stretch Blow Molding Machine is your choice of producing 5 gallon water tank either it’s one way bottles or reuseable bottle.Injection-stretch blow molding is a significant variation of this process. It is used to provide optimum optical and barrier properties, which are obtained through biaxial orientation of the polymer chains. This process is used primarily with polyethylene terephthalate (PET). Biaxial orientation is gained through the supplemental use of a stretching rod just prior to the bottle being blown. The rod allows the preform to be stretched in the vertical direction more uniformly than the blowing air allows.

Along with a reduced shipping cost, stretch blow molding offers many other advantages. A higher volume of output is able to be attained. A better control of dimensions is available and there is no bottom weld, which is created when an extruded parison is pinched shut by a mold.

- Dehumidifying and drying of PET materials.

- Injecting of molten raw materials into the preform mold by the injection machine.

- Cooling of molten PET preform to room temperature.

- Processing of preform by a finishing machine.

- Transferring of the preform to reheating stretch blow molding machines.

- Blowing high-pressure air into bottles with the use of metal blow molds.

Water, juice, carbonated beverages, and a wide range of other liquids, such as liquid soaps and detergents, are among the many things that are commonly packaged in plastic bottles using stretch blow molding. Having accessed the pros and cons of single-stage and two-stage blow molding machines, the choice of which to settle for will be dependent on what’s your priority.[4]

CMA(S) Series PET Automatic Stretch Blow Molding Machine is our standard machines for most common PET bottle production range from 600ml to 1500ml.CMSQ(W) Series PET Fully Electric Stretch Blow Molding Machine is designed for wide mouth jars production. The applications are nuts packaging、kimchi container、toys container…etc.

For more information or inquiry, please leave your contact information here or send us email for personal assistance.

REFERENCES

[1] C. Potash and P. Facilities, “Energy Benchmarking : Energy Benchmarking :,” 2018.

[2] V. Lohrbaecher and W. B. Hoven-Nievelstein, “Extrusion blow moulding,” Kunststoffe, Ger. Plast., vol. 78, no. 10, pp. 61–64, 1988.

[3] J. Biglione, Y. Bereaux, J. Y. Charmeau, R. G. Rinaldi, J. Balcaen, and S. Chhay, “Injection blow moulding single stage process - Approach of the material behaviour in process conditions and numerical simulation,” Key Eng. Mater., vol. 651–653, no. March 2016, pp. 805–811, 2015, doi: 10.4028/www.scientific.net/KEM.651-653.805.

[4] N. C. Lee, “Blow molding design guide,” p. 265, 2008.