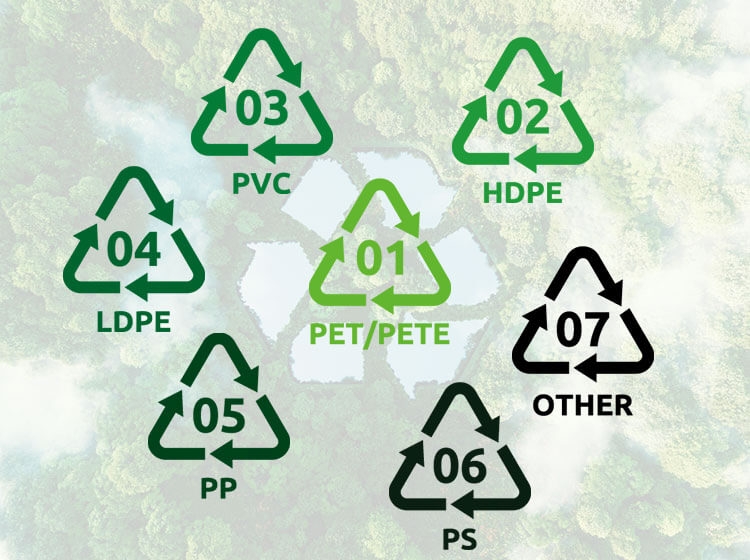

Material Information

Polyethylene Terephthalate

Characteristics

- PET is clear, tough, and has good gas and moisture barrier properties, resistance to heat.

- Commonly used in bottles and many food and non-food containers.

- Stiffness, strength, toughness, ease of processing, and ease of forming.

Packaging Applications

- Soft drink

- Water

- Sports drink

- Beer

- Mouthwash

- Catsup and salad dressing bottles

- Pickle, jelly and jam jars

- Cosmetic bottles

High Density Polyethylene

Characteristics

- Unpigmented bottles are translucent, have good barrier properties and stiffness, and are well suited to packaging products with a short shelf life.

- HDPE has good chemical resistance, it is used for packaging many household and industrial chemicals.

- Pigmented HDPE bottles have better stress crack resistance than unpigmented HDPE bottles.

Packaging Applications

- Liquid laundry detergent

- Shampoo conditioner

- Motor oil bottles

- Milk and juice bottles

- Yogurt and margarine tubs

Vinyl / Polyvinyl Chloride

Characteristics

- Poor heat stability.

- Molding and decomposition temperature range are similar.

- Poor fluidity, poor molding appearance.

- Corrosive to mold.

- Most easy to burn and generate acid gas.

- Good strength, electrical insulation and chemical resistance.

- Can be softened after adding DOP.

- Poor heat resistance.

- High sp. Gravity (1.4) has burning resistance; good for printing

- Different formula has different characteristics. Wide application range, low price, high impact to environment. Likely to decompose when molding temperature exceeds 190°C and emit corrosive gas of HCI.

Packaging Applications

- Clear food and non-food packaging

Low Density Polyethylene

Characteristics

- High shrinkage, easy to bend and deform.

- Need cooling time, poor molding yield.

- Sink will occur to product, need forceful mold releasing.

- Molding shrinkage is highly affected by mold temperature. Poor stability.

- Good fluidity, good heat stability, but molecular orientation leads to distortion.

- Lighter than water and soft.

- Not heat resistance, adhesive printing.

Packaging Applications

- Squeezable bottles (e.g. honey, mustard)

Polypropylene

Characteristics

- Low fluidity, flow mark appears if filling were poor, when pressure is not enough, easy to have dent, need high-pressure molding.

- In optical use, transparency is a problem, when mixing with other material; care shall be given to decomposition.

- Excellent in molding property, mechanical strength is better than PE.

- Good water, chemical resistance and electrical insulation.

- Easy to distort, deform and dent.

- Adhesive, the lightest plastic.

- Low Sp. Gravity (about 0.90), FDA grade, good transparency, no moisture absorption, low price, heat resistance and normal mechanical strength are poor, low foaming percentage, poor for printing.

Packaging Applications

- Catsup bottles

- Yogurt containers

- Margarine tubs

- Medicine bottles

Polystyrene

Characteristics

- Of Ethylene family, general plastic resin.

- Good fluidity, good molding yield and molding property.

- Easy to break, not good impact resistance.(GPPS)

- Easy to trim.

- Colorless, transparent, easy to be dyed, and good insulation.

- Good in water resistance and chemical resistance.

Packaging Applications

- Aspirin bottles

Characteristics

Use of this code indicates that the package in question is made with a resin other than the six listed above, or is made of more than one resin listed above, and used in a multi-layer combination.

Packaging Applications

Dependent on resin or combination of resins