CM-L Series Continuous Extrusion Blow Molding Machine

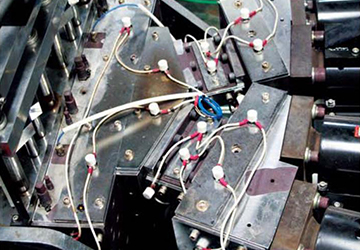

Continuous Extrusion Blow Molding Machine

CM-L Series - (Multi-layer / Co-Extrusion)

CM-L Series

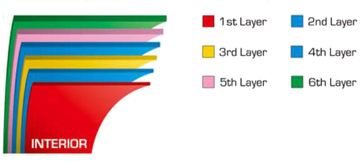

CM-L Series multiple layers co-extrusion blow molding machine is specified for producing particular containers that are fully sealed, light resistive, heat resistive, anti-bacterial, durable, anti-static, corrosion resistive, non-toxic, etc.

| CM-L Series Continuous Extrusion Blow Molding Machine | |

|---|---|

| Bottle Capacity | Output BPH(pcs/hr) |

| <300ml | <3000 |

| 300ml~500ml | <3000 |

| 500ml~1L | <3000 |

| 1L~2.5L | <3000 |

| 2.5L~5L | <800 |

| 5L~10L | <800 |

| 10L~25L | <400 |